What type of shears are chunking shears – Chunking shears, a specialized cutting tool, play a vital role in various industries and applications. Their unique design and functionality make them indispensable for tasks requiring precise and efficient cutting. This comprehensive guide delves into the world of chunking shears, exploring their purpose, evolution, types, applications, key features, operation, maintenance, and comparison with other cutting tools.

Get ready to uncover the versatility and effectiveness of chunking shears.

From their humble beginnings to the latest advancements, chunking shears have undergone a remarkable journey. Today, they come in a range of types, each tailored to specific cutting needs. Whether it’s heavy-duty industrial applications or delicate crafting projects, there’s a chunking shear designed to excel.

Chunking Shears: Overview

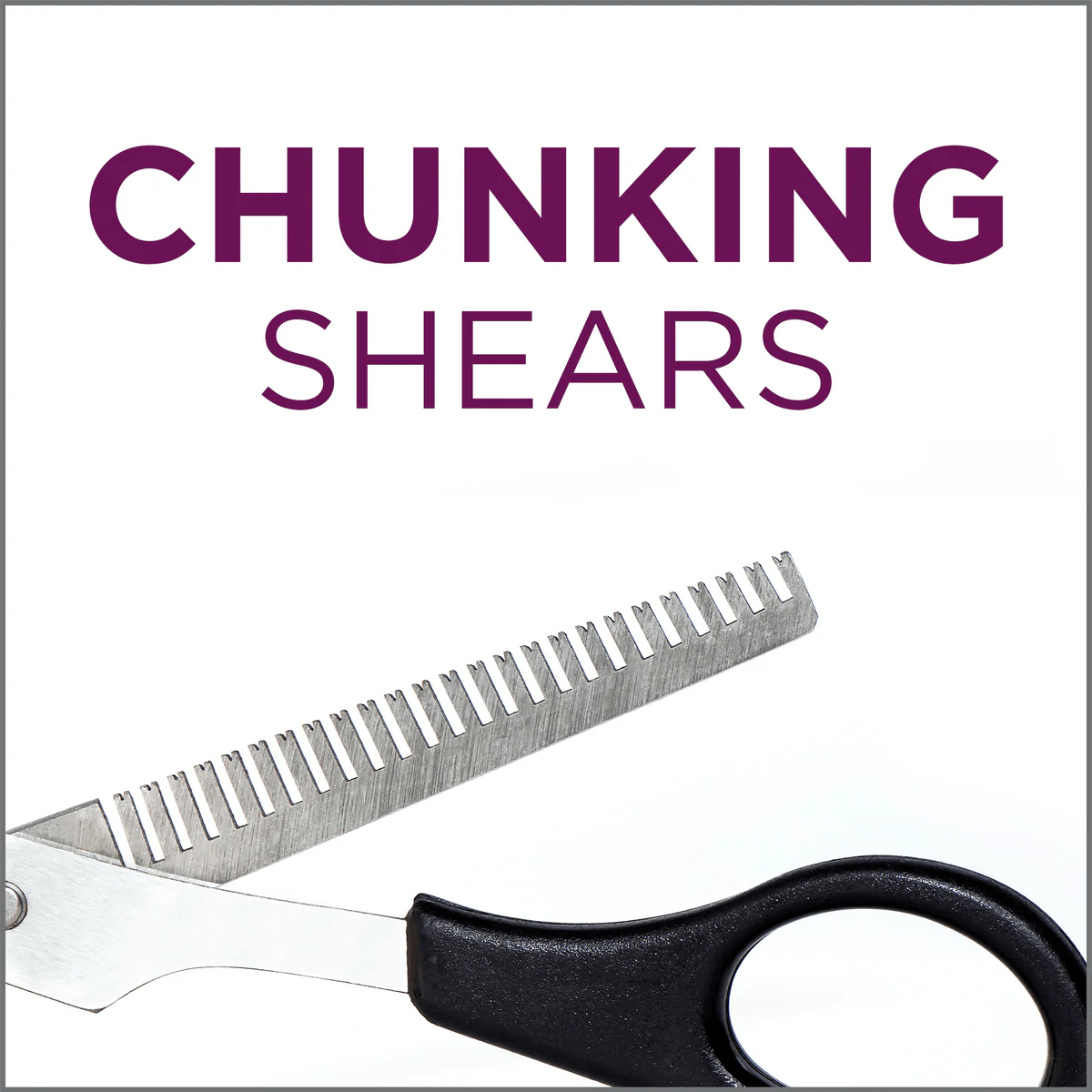

Chunking shears, also known as chunkers or chunk cutting shears, are specialized cutting tools designed to efficiently process large pieces of material into smaller, manageable chunks.

The history of chunking shears dates back to the early 20th century, with their origins in the meat processing industry. Over time, they have evolved to serve a wide range of applications in various industries.

Chunking shears come in various types, each tailored to specific materials and cutting requirements. These include:

- Manual chunking shears: Operated by hand, these shears are suitable for smaller-scale operations and cutting softer materials.

- Hydraulic chunking shears: Powered by hydraulics, these shears offer greater cutting force and are ideal for processing larger, tougher materials.

- Pneumatic chunking shears: Utilizing compressed air, these shears combine power with portability, making them suitable for various industrial settings.

Applications of Chunking Shears

Chunking shears find widespread use across diverse industries, including:

- Meat processing: Cutting meat into smaller portions for packaging and distribution.

- Recycling: Processing scrap metal, plastics, and other recyclable materials into smaller pieces.

- Construction: Cutting rebar, metal beams, and other construction materials.

- Automotive: Processing scrap metal and cutting parts during vehicle manufacturing.

- Textile: Cutting large rolls of fabric into smaller pieces for garment production.

The advantages of using chunking shears include:

- Improved efficiency: Chunking shears allow for rapid and effortless cutting, significantly reducing processing time.

- Enhanced productivity: By streamlining the cutting process, chunking shears enable increased output and productivity.

- Versatility: Different types of chunking shears cater to a wide range of materials and cutting requirements.

Key Features and Components

Essential features and components of chunking shears include:

- Blades: The cutting blades are typically made of high-quality steel, ensuring durability and sharpness.

- Handle: The handle provides a comfortable and secure grip for the operator.

- Cutting head: The cutting head houses the blades and is designed to withstand high cutting forces.

- Power source: Manual chunking shears rely on manual force, while hydraulic and pneumatic shears utilize external power sources.

- Safety features: Chunking shears often incorporate safety features such as blade guards and anti-slip handles.

The materials used in the construction of chunking shears vary depending on the intended application. High-strength steels are commonly used for blades and cutting heads, while lightweight materials like aluminum are employed for handles.

Operation and Maintenance

Proper operation and maintenance of chunking shears are crucial for optimal performance and safety.

Operation guidelines include:

- Wear appropriate safety gear, including gloves and eye protection.

- Secure the material to be cut properly before operating the shears.

- Apply appropriate force and avoid overloading the shears.

Maintenance procedures include:

- Regular cleaning and lubrication of moving parts.

- Sharpening or replacing blades as needed.

- Inspecting safety features and ensuring they are in good working order.

Comparison with Other Cutting Tools: What Type Of Shears Are Chunking Shears

Chunking shears offer distinct advantages over other cutting tools used for similar applications:

| Feature | Chunking Shears | Other Cutting Tools |

|---|---|---|

| Cutting force | High | Varies |

| Speed | Fast | Varies |

| Versatility | Wide range of materials | Limited to specific materials |

| Safety features | Integrated safety features | May lack comprehensive safety features |

Market Trends and Future Developments

The market for chunking shears is driven by the growing demand for efficient and productive cutting solutions in various industries.

Current trends include:

- Increasing adoption of hydraulic and pneumatic chunking shears due to their power and efficiency.

- Development of compact and portable chunking shears for enhanced versatility.

- Integration of advanced technologies, such as sensors and automation, to improve safety and productivity.

Future developments may include:

- Self-sharpening blades to minimize downtime and maintenance.

- Remote monitoring and control of chunking shears for improved safety and efficiency.

- Exploration of new materials and designs to enhance durability and cutting performance.

Question & Answer Hub

What are the primary applications of chunking shears?

Chunking shears find widespread use in industries such as metalworking, construction, automotive, and crafting. They are particularly effective for cutting sheet metal, trimming excess material, and creating intricate shapes.

How do chunking shears differ from other cutting tools?

Chunking shears are distinguished by their unique blade design, which features a series of closely spaced teeth. This design allows for clean and precise cuts, reducing the need for additional finishing or deburring.

What are the key factors to consider when selecting chunking shears?

When choosing chunking shears, consider the material you’ll be cutting, the thickness, and the desired cut quality. Additionally, factors such as blade length, handle ergonomics, and safety features should be taken into account.